MAC's Believe It Or Not!

by John "Mac" McDougald

Reprinted from "Crown Jewels of the Wire", December 1994, page 15

The original home of some incredible insulators were the shelves that

contained experimental production samples in Millville, New Jersey. Sometime

before the closing of the Whitall Tatum - Armstrong - Kerr factory, the insulators

were put in boxes and removed to the utility shed of a company employee. The

gentleman had had access to the samples during his employment. Twenty years

later, the utility shed in southern Jersey relinquished its hold on boxes that

had been crushed by the weight of multiple boxes piled upon one another for

several decades.

Bob Moss of Millville now owns those experimental insulators

and generously brought them to the eastern regional show in Kulpsville,

Pennsylvania in September. Trying to uncover the stories behind each of these

unique pieces has been aided by the research of Richard Wentzel, who has

contributed greatly to the hobby's knowledge about glass production in

Millville. Also, Bob has had several conversations with Earl Dubois, now

eighty-five years old, who was a mold maker and later Armstrong's insulator

sales representative until he retired in 1945. Dubois was credited with the

design of the CD 203 TW, which was designed to replace Hemingray's CD 197 No.

15.

As many collectors huddled around Mac's photographic light box, Bob began to

remove the Millville insulators from their boxes. One of the first items to

emerge was a peculiar, unembossed "X"-shaped piece of clear flint

glass with two separate copper wires embedded in the glass. Showing the piece to

Dick Bowman and asking him to speculate as to its intended use, Dick made some

attempt to find a water source with it right there in the kitchen of the

Kulpsville fire hall.

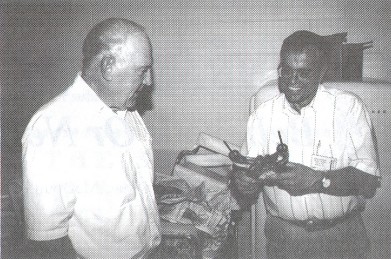

Bob Moss and Dick Bowman examine the

glass "X" mid-span transposition piece.

Actually, the piece was a design of Earl Dubois who was attempting to develop a mid-span transposition insulator to compete with

Hemingray's four pin bracket that contained four CD 1049 insulators. The

Millville edition never succeeded beyond the experimental stage because it was

not versatile enough to be attached to a crossarm! Believe it or Not!

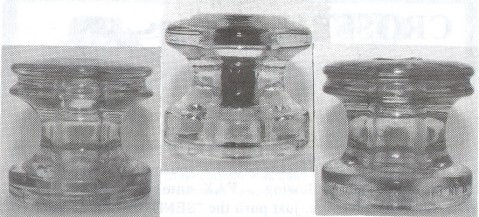

Bill and

Jill Meier of Carlisle, Massachusetts eagerly awaited the Whitall Tatum CD 221

to emerge. They had recently purchased a CD 221 Hemingray-68 that had an

aluminum coating applied above the wire groove. In comparing the Hemingray piece

with the Whitall Tatum item, several differences were noted.

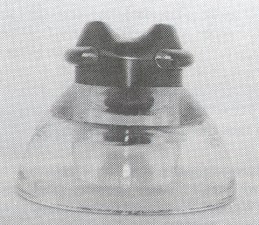

The Hemingray piece (left above) has a shallow lip on the upper wire ridge while the Whitall Tatum piece

(right) is smooth. The Hemingray piece is embossed Hemingray-68 while the one

from Millville has only the number "68" on the skirt. The mold line

also are 90° opposed to each other.

Earl Dubois indicated that the

"68" was an attempt to copy the Hemingray product. Research of

documentation has uncovered correspondence which indicated that Hemingray and

Whitall Tatum were considering a collaboration using the Hemingray patent

processes developed in connection with aluminized tops for power insulators.

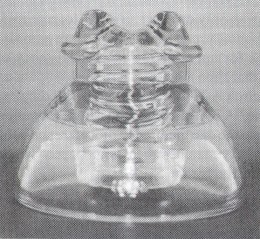

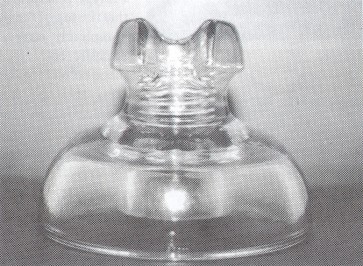

Those who have studied the photo of CD 240.2 in Insulators: A History and Guide

to North American Pintype Insulators will note that the top of the insulator is

completely covered with a metallic copper cap. This piece belongs to Joe Maurath

who obtained it from the Armstrong offices many years ago. (A story in itself --

stay tuned next month!) At the time of the writing of the two-volume

reference guide, I knew of only three of these pieces. Each was different either

because of the embossing or the metal cap.

However, two CD 240.2 pieces which premiered at Kulpsville were different

from the original three. The one at the top has a cap similar to the Maurath

piece. It is embossed "1025" on the skirt. The second piece is clear

and is also embossed with "1025" on the skirt. The last piece also has

a completely coated top, but is coated with a chromium-looking substance and not

with copper. Believe it or Not!

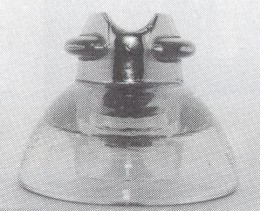

The next piece brings me to "True

Confessions" time. When Mrs. Mac and I were putting together our reference

book, Richard Wentzel shared with us an insulator and the design drawings for an

Armstrong product numbered 51C4. However, there was no embossing on Richard's

insulator. In fact, there was not even a back half to Richard's insulator!!!

In

our attempt to complete as many new CD assignments as possible before

publication, we sent a shadow drawing, photo and design specifications to N .R.

"Woody" Woodward for his scrutiny and CD assignment. Woody

"birthed" CD 238.2 and the photo appeared in our reference" book.

Of course, unbeknownst to you readers and (I confess to you, Woody), there was

only one half an insulator pictured.

As with many experimental production, there

were samples that were sawn in two to check for imperfections and consistency of

production and design. Since that time the "back half' has shown up and it

had an embossed "A in a circle". NOW, Bob Moss has a complete" CD

238.2 and it shares the same "A in a circle" embossing. However, the

ears are slightly different than the one pictured in the reference book and looks

as though it more closely matched the design papers which possibly makes

it the original design for the 51C4B.

And just when you thought you had seen everything that came out of Whit all

Tatum, look! Spools! And apparently they were serious about getting into the

spool business. Two distinctly different styles were produced. The style without

the groove is in a beautiful ice blue, and the grooved specimens are in straw

and a light smoky color. Are we sure they are Whitall Tatum products! You bet.

In case you haven't had your glasses prescription updated recently, the spool

on the right is embossed on the base, "Whitall Tatum Co. No 16. And we will

have more to share from Bob Moss' super find next month! Believe it or Not!

|